POWER GEN PRODUCTS & SERVICES:

FUEL GAS BOOSTER ENHANCEMENTS

IMPROVE YOUR POWER GEN COMPRESSORS’ RELIABILITY,

EFFICIENCY, AND ENVIRONMENTAL SOUNDNESS

For companies looking at ways to better manage emissions, our comprehensive Power Gen solutions can help optimize your compressors while minimizing their environmental impact, making your operations greener and cleaner.

Are your compressors optimized for efficiency and environmental soundness?

A growing number of countries around the world are instituting new guidelines to reduce emissions from their electrical generation stations, as part of international initiatives to reduce greenhouse gases and slow down the impacts of global warming. HOERBIGER Power Gen solutions can help you reach the next level of compressor efficiency in more environmentally-compliant ways.

Focused on your Power Gen needs

HOERBIGER has an optimized solution for every service application. Recognizing that customers’ needs follow different requirements, we have developed appropriate services to address these needs. We call this PerformanceXperience® – PX for short. Our services provide measurable and long-term improvements in the efficiency, reliability, and environmental soundness of your compressors. Services from HOERBIGER are designed to allow you to focus on what you do best: running your unit profitably. You benefit from the advantages of genuine performance.

MORE INFORMATION

REE: AN IDEA BECAME OUR MISSION

REE is an integrated engineering approach that is unparalleled in the oil and gas industry. We focus not only on individual components or compressors, but on their interaction in the plant processes.

In our unique and in-depth REE Audit, HOERBIGER experts analyze and benchmark existing machines, and identify opportunities to optimize reliability, efficiency and environmental soundness. More Information

MORE INFORMATION

The one-stop shop:

For your short and longer-term

product, service and field service needs

Are you looking for an uptime increase for your compressors in power generation applications?

HOERBIGER is the ideal partner to package the right solution for you. Based on state of the art products,

we can offer you upgrades that will significantly improve your compressors, and double their lifetime by an upgrade of designated key components.

And the best thing: it is easy too – HOERBIGER takes care it all – from selection,

to delivery and installation of the new genuine parts.

With dedicated service branches across the U.S. and Canada, HOERBIGER is close by when and where you need us, with U.S. locations in Santa Clarita, California; Casper, Wyoming; Liberal, Kansas; Odessa and La Porte, Texas; Baton Rouge, Louisiana; and Joliet, Illinois. Our Canada service centers are located in Edmonton, Alberta; and Mississauga, Ontario.

CP VALVE: THE NEW STANDARD IN NG COMPRESSION

Conventional valve designs have outlived their purpose when it comes to increasing compressor efficiency.

Real increases in efficiency can only be achieved through innovative, smaller designs –

which place high demands on all their components.

The profiled plate of the CP valve enables a valve

porting design that streamlines the path of the gas through the valve when open. The design, manufacture,

and support of this technology completely revolutionizes gas compression reliability. It surpasses all

previous valves in durability without sacrificing efficiency over a wider range of operating conditions.

HOERBIGER CP valves are a prerequisite for greater compressor efficiency and reliability.

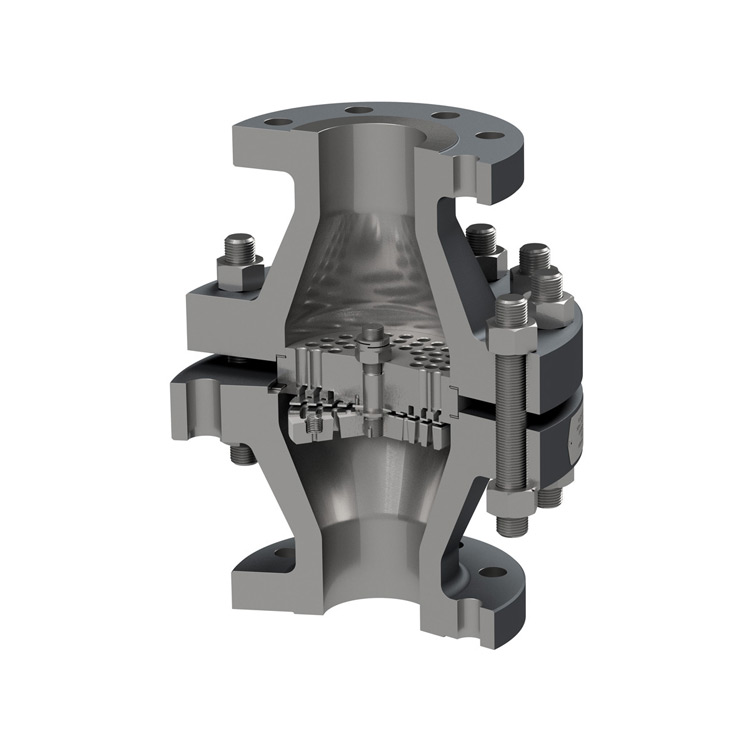

NON-SLAMMING CHECK VALVE: THE LATEST ADVANCEMENT FOR REGULATING FLOW

Check valves are critical devices that not only prevent equipment damage, but also reduce safety risks caused by reverse flow. There are a number of check valve types available today, but our customers’ engineering teams are usually challenged to select technologically advanced, yet economical solutions for their specific applications. HOERBIGER check valves, an industry standard for more than 70 years, offer the latest advancements in better regulating pulsating or turbulent flow conditions- quickly and efficiently.

MORE INFORMATION

HYDROCOM: MORE EFFICIENT CAPACITY CONTROL AND HIGHER ENERGY SAVINGS

Conventional capacity control systems, such as step control or spillback valves, are imprecise and waste energy. HydroCOM provides stepless capacity control of a reciprocating compressor, which improves process controllability, reduces power consumption and can be fully integrated into the plant’s control system.

MORE INFORMATIONBCD RING PACKING DESIGN AND IMPROVED MATERIAL TECHNOLOGY FOR RING AND RIDER UPGRADES

Pressure packing, piston rings and rider bands: Increase life and reduce emissions

HOERBIGER is a world leader in designing, manufacturing and servicing pressure packing, piston rings and rider bands, and we design and test our sealing systems for the most challenging operating conditions: from chemically inert to highly reactive gases, from cryogenic to high operating temperatures, from bone-dry to wet conditions, and from vacuum to high pressures. We offer a comprehensive line of standard ring and packing sealing systems that optimizes sealing performance and component life.

MORE INFORMATION

Advanced material technology and expertise:

Ensures the highest-quality components

At the HOERBIGER Polymer Research Center, scientists, application engineers and production specialists work together to solve our customers’ reciprocating compressor sealing problems for virtually all gas and operating conditions, and our years of experience allow us to offer the best material selection available today. We carefully select premium, raw materials and process them into reliable and durable components that meet every expectation for long, effective lives.

Compressor components crafted from our HY Experience Class Materials stand out thanks to their low wear rates, and long lifespans, and our Highest Performance Materials are formulated to perform in the highest range of operating conditions of all families of compressed gases in the most challenging environments.

MORE INFORMATION

MORE INFORMATION

XPERLUBE: WORRY-FREE, SMART COMPRESSOR LUBRICATION

Bringing cylinder lubrication and compressor reliability into a harmonious means to disconnect oil dosing from oil pumping correctly.

Improper cylinder lubrication leads to premature wear and malfunction of sealing elements or even damage to capital parts, and both can cause unplanned compressor stops and costly production interruptions. XperLUBE always injects the user-specified amount of oil: not more, not less - even when operating conditions such as oil temperature or cylinder pressure change.

MORE INFORMATION

Global expertise – local know-how

With dedicated service branches in over 40 countries, HOERBIGER is close by when and where you need us.

As part of our ongoing customer service commitment, we share our comprehensive knowledge and expertise

about compressors and their components with our local customers to help maximize your compressors’ reliability,

efficiency and environmental soundness.

The HOERBIGER service advantage: At HOERBIGER, service is not about just repairing our customer’s components. It’s about meeting all of your short and longer-term service needs – by assessing component wear patterns and service histories, and identifying ways to increase reliability. With our comprehensive expertise, we can help optimize your compressors. Our highly skilled technicians and best-in-class engineering experts can offer and deliver the upgrades you need to reach the next level of compressor operation.

Contact Person

Head of Sales - Service North America

Darren Sudduth

Telephone +1 713 819 2746

Send email